upper image

Targets the design and development of a novel centralized, reliable and upgradable in-vehicle electronic control architecture (ECA).

Paradigm shift to a centralized, upgradable, HW/SW co-design driven ECA

Enables smart data flows and ensures safe and cyber-secure operation

Combines a SW-driven top-down approach with a HW-driven bottom-up approach

Creates the foundation for SdVs realizing a service-oriented architecture

Cooperates along the complete CCAM value chain

Explores harmonization and standardization activities

Pushes international cooperation and builds on results from previous projects.

Project start 01.06.2025

Duration in months

Project Partners

Involved Countries

Budget in M€

Project Use Cases

Impact Results

Objectives

-

Obj. 1

- Development of a new, centralized, and upgradable design for future in-vehicle ECAs based on HW/SW co-design enabling smart data flows to maximize efficiency, modularity, compatibility, and scalability.

-

Obj. 2

- Exemplarily deployment of level 4 automation use cases characterized by expanded ODDs addressing complex urban scenarios and adverse weather conditions and harmonized validation methods. .

-

Obj. 3

- Enable a safe and cyber-secure operation of future CCAM solutions through system agility, experience-based decision making enabled by distributed intelligence in the edge-cloud continuity focusing on VRUs and ODD transitions.

-

Obj. 4

- Realize a paradigm shift to integrated, resource efficient and reliable in-vehicle electronics control architectures based on open-source layouts enabling an easier development and integration of connected and automated driving functions.

-

Obj. 5

- Set up an international cooperation of European OEMs and suppliers to co-design a harmonized ECA layout with harmonized interfaces.

Development Infrastructure

- Software developement infrastructure

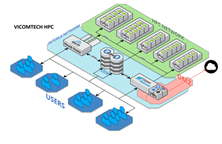

- HPC cloud infrasturcture for data management

- XiL testing and validation

INT SW development infrastructure

IFAG/IFAT Laboratory

IDI simulator

VICOM simulator

VED Lab environment

VICOM HPC

Demonstrator vehicles

- Access to fully equipped CCAM vehicles including the entrie software stack

- Access to E/E architectures including sensors and raw data

- Developement on vehicle level

Valeo Vehicle

Vicom Vehicle

IDI Vehicle

VED Vehicle

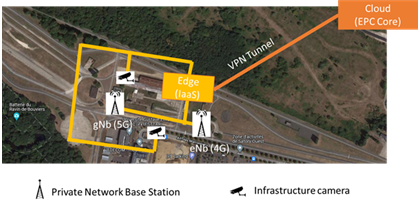

Testing Infrastructure

- Controlled scenario execution

- Diverse testing conditions (ODD) applicable

BCCAM testing infrastructure (ES)

VED proving ground (FR)

VALEO proving ground (DE)

IDI proving ground (ES)

Methodology

Iterative development – 2 main cycles each consisting of 4 stages

1st cycle

early prototyping and testing

2nd cycle

builds on learnings from the first cycle to extend individual functionalities

Key success factor

Impact and management activities interface with technical developments